Tracker 101: intro to Idle Air Control (IAC)

#1

CF Senior Member

Thread Starter

There are several types of Idle Air Control (IAC) valves. Some use a servomotor and some use a stepper

motor. Either way the motor turns a shaft that drives a plunger called a "pintle" to regulate the amount of

air bypassing a closed throttle plate.

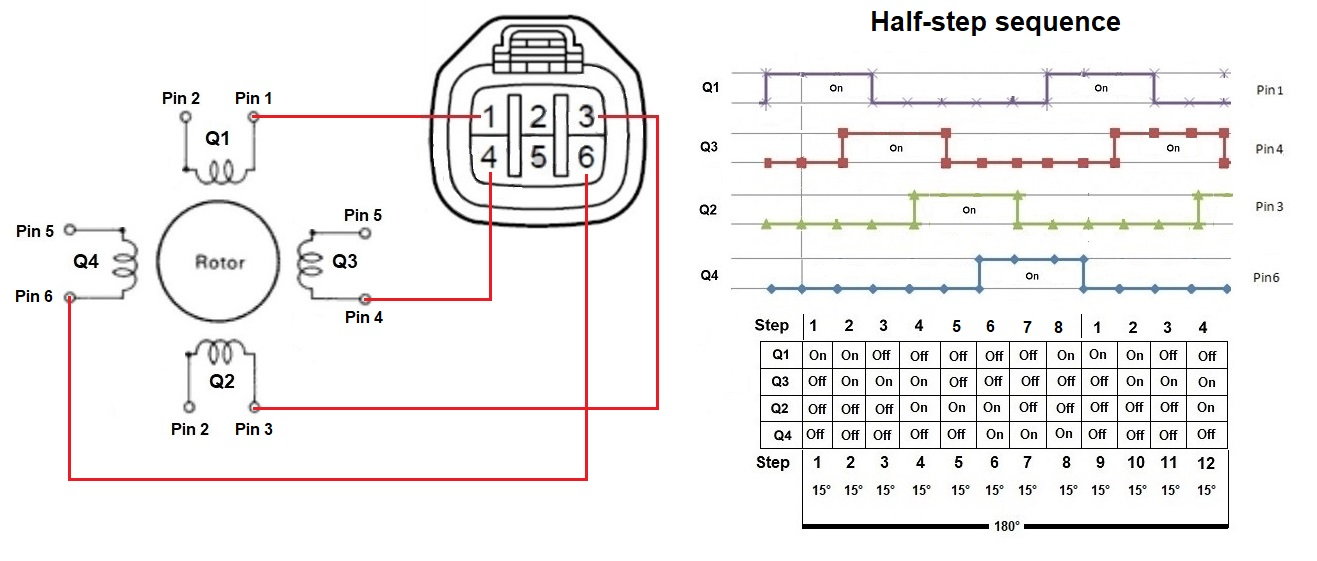

Most Trackers uses this 6-wire Idle Air Control (IAC) valve. This is a unipolar stepper motor because the current only flows in one direction.

The transistor switches inside the PCM are single-throw (ON/OFF). Bipolar stepper motors use double-throw switches to reverse the

current. In their own cars, Chevy likes to use a 4-wire bipolar stepper motor but that is not the case for the Tracker.

Pins 2 and 5 of the IAC supply 12 volts to the top of the four phase coils. The other four wires are the digital stepper motor

control signals from the PCM. The PCM's internal switches (Q1 thru Q4) are either on or off. Note that Q1 is

open while and Q2 is closed. Both transistors change state simultaneously so there is never a time

when both are conducting at the same time. Q4 and Q3 operate in a similar manner.

This is an IAC valve for a Toyota. It appears to be the same as the one in my Tracker.

The output from the PCM is issued in half-steps. Each half-step rotates the stepper motor 15°. After eight unique steps the pattern repeats.

It takes twenty-four half-steps to rotate the stepper motor one full turn. Full extension of the plunger shaft takes about five turns of the stepper

motor. To drive the stepper motor counter-clockwise the PCM only has to run the switching sequence in reverse. Pausing the sequence

will hold the pintle in it's last position. Q1 and Q2 can never be ON at the same time. Likewise, Q4 and Q3 can never be ON at the same

time.

This .gif animates the half-step sequence.

The stepper motor adjusts idle speed by opening and closing the IAC valve.

The tapered pintle pushes into a correspondingly tapered seat. The more

the pintle retracts, the more air is bypassed around the closed throttle plate

increasing the idle speed. The IAC valve has no effect on engine speed

after the throttle plate opens.

The PCM looks at more than a dozen inputs in deciding where to position the IAC. The computer knows the position of the pintle by keeping track of the

number and direction of the steps it has sent.

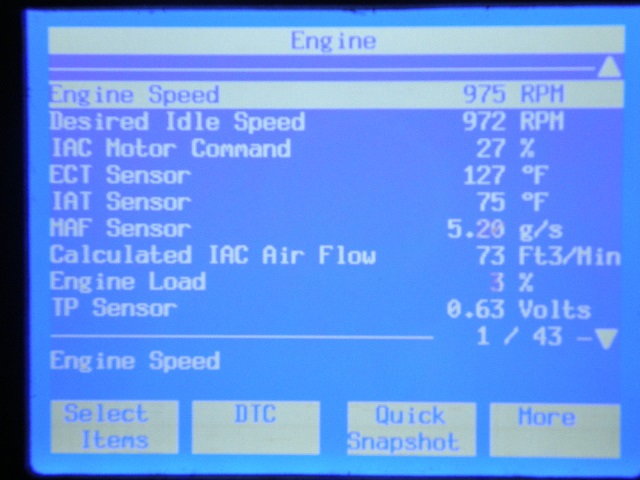

Some cars/scanners display the number of IAC steps. My Tech2 displays the IAC Motor Command

as a percentage. With the Key On, Engine Off (KOEO) the IAC was at 46%. I'm assuming that's its

starting position. With the engine running at a temperature of 105° the IAC percentage had dropped

down to 32%.

By the time the temperature reached 127° the IAC percentage was down to 27% and the idle speed

was down to 975 RPM. The normal operating temperature for my engine is 199° with an idle speed

around 675 RPM but I didn't leave it running that long. However, as a test of the PCM/IAC

responsiveness, I turned on the air-conditioner to see what would happen. The IAC percentage

immediately jumped up to 38% then slowly came back down.

The Chevy service manual says the acceptable range for the IAC command is between 10% and 50% so I guess mine is working okay. Unfortunately the Chevy manual

also says the Tracker IAC uses PWM and that is not true.

Last edited by L84sky; February 15th, 2023 at 7:00 AM.

#2

CF Senior Member

Thread Starter

If you have access to page 6-1735 of the 2001 Chevy Tracker factory service

manual you will find an IAC theory of operation (above) that is incompatible

with the V6 Tracker's actual IAC. That's because the Suzuki manual does not

provide theory so Chevy just lifted one from a vehicle using a completely

different type of valve.

I don't know what vehicle they took it from but the IAC

they describe is similar to one used by Ford. The Ford

idle Air Bypass Valve is not a stepper motor. It is a

computer controlled on/off solenoid that operates

much like a fuel injector but for air.

The PCM fires a pulse 200 times a second. The "on time" of the pulse

(T') determines how long the solenoid stays open. As the PCM increases

the duty cycle more air is allowed to flow past the throttle plate increasing

the idle speed. This type of valve control is called Pulse Width Modulation

(PWM) and my Tracker does not use it.

Thread

Thread Starter

Forum

Replies

Last Post